- INSPECTION SYSTEMS FOR SECURITY SUBSTRATES

- Top quality of security substrates & printing

- Enhanced Threads Inspection add-on

- BankSTAR Color: Off-color detection

- BankSTAR RS: Sheet format inspection

- BankSTAR TS: Thread slitting inspection

- Production analytics - Data-driven efficiency

- Service solutions and individual trainings

- Contact our experts

Top quality of security substrates & printing

Security papers, security films, security elements and security printing must adhere to rigorous quality standards for perfect counterfeit protection. Sub-standard quality and defects result in costly complaints and rejects. Therefore, compromising manufacturing precision significantly reduces productivity and revenue.

Learn how to achieve the highest inspection reliability for security paper, security foil and all applied security elements along with a short ROI, fast setup and easy operation.

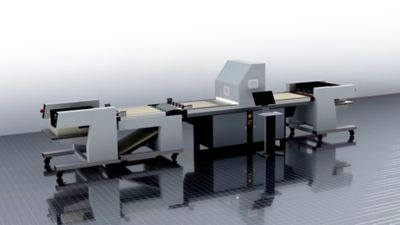

The BankSTAR product line is the only inspection system specifically tailored to the requirements of the security printing and substrates industry. It provides the highest inspection reliability for security paper, security foil and all applied security elements.

Enjoy the confidence of 100% substrate inspection from the global #1 in banknote paper inspection and obtain unsurpassed holography inspection performance, trusted by the leading manufacturers of security threads and diffractive security features.

BankSTAR secures quality by inspecting the surface and security elements of the material. Defects are identified at the earliest possible stage. Productivity is optimized by excluding sub-standard material from further processing. High-end technology components deliver precise and reliable inspection results at any stage within the production process.

But, BankSTAR serves not only as an high-end inspection tool before shipping to your customer, the different systems also help to significantly optimize production efficiency and reduce costs.

BankSTAR in-line inspection systems can also go on a conveyor/sorter platform to make an autonomous stand-alone solution.

Recent additions to our constantly growing BankSTAR solutions portfolio include:

Enhanced Threads Inspection add-on

Finally, there is a solution to what previously had been beyond the scope of in-line automated optical inspection: The Enhanced Threads Inspection add-on for our acclaimed BankSTAR banknote paper inspection verifies the manufacturing quality of embedded and windowed security threads.

Besides the up to 16 checks on security paper thread zones that BankSTAR has been performing anyway, revolutionary new algorithms are now employed to verify the thread décor for defect-freeness, detect thread slitting errors and trace thread fluorescence.

The Enhanced Threads Inspection add-on thereby not only cures a major headache of security paper manufacturers, as security threads cannot be subjected to an incoming inspection before they are inserted into the substrate, but also has the potential of saving paper mills hundreds of thousands of Euro in rejections and wastage due to flawed thread quality.

The Enhanced Threads Inspection add-on makes this quantum leap in banknote paper inspection available to paper makers with just a minor hardware upgrade – mainly, an extra PC for running the additional algorithms – and a quick and easy software update.

Enhanced Threads Inspection is available for BankSTAR Gen4, our latest product generation, and can be deployed at the wet section or dry end of the paper mill, as well as at the cross-cutter.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

asdf

asdf

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

test123

test123

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

BankSTAR Color: Off-color detection

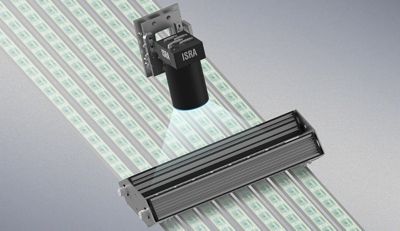

The detection of off-colors has been an increasing concern of security paper manufacturers. Fluorescent security fibers and extremely low-contrast stains do not differ from the substrate or from one another by grey value, but only by color. Adherence to rigorous quality standards and customer demands therefore requires color evaluation alongside contrast-based inspection.

BankSTAR Color allows the free defintion of color spaces to distinguish between correct colors and off-colors. Unwanted security fibers - visible or UV-reactive - are faithfully detected by dedicated hardware processing in near real-time at even the highest web speeds. Correctly colored security fibers are tolerated. By the same token, oil stains and other off-color contaminations are found even if their grey value is the same as the substrate's.

BankSTAR Color is the perfect companion for BankSTAR WS, PM, OV and CC, adding a one-of-a-kind color feature to security substrate inspection.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Low maintenance requirements

- Avoid adding value to waste material

- Defect detection on security paper, security foil and on all applied security elements

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

- Technical data 1

- Technical data 2

- Technical data 3

- Technical data 4

- Technical data 5

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

BankSTAR RS: Sheet format inspection

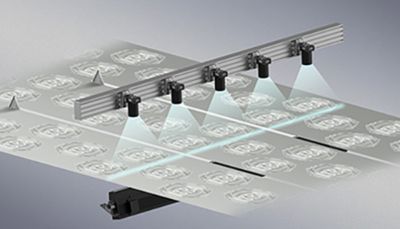

This innovative new inspection solution helps to optimize the trim position of the roll slitter with sheet format inspection.

Incorrectly cut paper rolls lead to significant waste and reduce your throughput – lowering both productivity and yield.

BankSTAR RS ensures exact position control of slitting and trim. It detects even the smallest object positioning deviations and defects.

BankSTAR RS is the only solution for performing format inspection on the roll slitter that helps you avoid waste, increase productivity and gain process control.

Benefits

- Short ROI, quick setup, easy usability

- Complete process monitoring and yield optimization

- Defect detection on security paper, security foil and on all applied security elements

- Low maintenance requirements

- Avoid adding value to waste material

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

BankSTAR TS: Thread slitting inspection

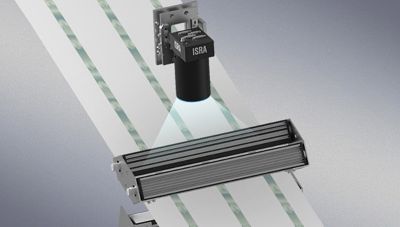

Automate optical inspection on the thread slitter with a highly specialized thread inspection behind the slitting knife. This new inspection system inspects both the slitting position and the content of the threads on the pancake roll.

The special image-processing algorithm checks each thread separately, tolerating thread oscillation. This enables perfect quality control as each single thread is checked for immaculate quality.

In addition, perfect process control helps re-adjust the knife before the slitting position goes out of tolerance. Reduce quality claims and the associated cost by ensuring that only material meeting your customer´s quality standards is passed along the process chain and shipped.

Benefits

- Low maintenance requirements

- Short ROI, quick setup, easy usability

- Defect detection on security paper, security foil and on all applied security elements

- Avoid adding value to waste material

- Complete process monitoring and yield optimization

- Inspection at highest processing speeds and real-time classification

- Features

- Typical defects

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Cutting/slitting defects

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

Production analytics - Data-driven efficiency

The web-based production analytics platform allows you to check the system status of all production lines at a glance or analyze production data in detail. With the quality management system, you analyze historical data, monitor current inspection data in real-time, and identify future trends in your production process.

Early detection of production defects

Detect and quickly identify the cause of threshold value violations at every stage of production with live status information and automatic alerts. As a result you can quickly resolve production defects, shorten downtime, and reduce production costs.

Predictive maintenance

You can prevent potential system failures by analyzing real-time data from the sensors and monitoring systems. This allows proactive planning of maintenance, based on the actual condition of the machines, instead of following a fixed schedule. This data-driven approach saves costs through reduced downtime and increased overall productivity, as well as longer production line life.

Optimization of production

Dashboards allow you to compare production line and product data onsite or remotely, providing key insights for optimization. This enables you to make informed professional decisions along your value chain to increase the product quality as well as profitability. You can continuously track the progress of optimization measures and present them with visualized advanced reports.

Your benefits

- Time-saving multi-line overviews, one view for all quality-related information

- Minimize downtime by monitoring system health data

- Faster reaction to quality issues with quality data monitoring

- Fast elimination of production defects, reduction of production costs

- Improved maintenance for reduced downtime, higher overall productivity and longer production line life

Key Features

- Overview on production data and plant status

- Live insights from real time data

- Department oriented dashboards, customer specific adaptations are possible

- Web-based solution, no client software installation required

- Threshold monitoring and alerting

- Open to integrate relevant third-party data and export data to the customer's systems

Service solutions and individual trainings

For the efficient and future-proof operation of your production systems our highly qualified service teams support you globally in all matters. We provide the implementation, maintenance and servicing as well as the analysis and optimization of your systems.

Learn in the ISRA VISION Academy how our competent trainers always keep your employees up to date with the latest knowledge so that system operators, product engineers and quality managers become real inspection experts.