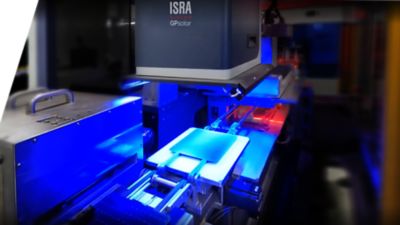

Final quality sorting for solar cell manufacturing

Cell sorting at the end of the line is mandatory for high-value modules of homogenous color. The CELL-Q inline inspection system checks the front or back of solar cells and sorts them into different color and performance classes according to their optical properties. In a single inspection step, CELL-Q checks the print quality and anti-reflection coating of every single solar cell.

All print and color defects are reliably detected for all cell technologies. Additionally, both the surface and the contour are checked for visible defects. This ensures that only homogeneous cells regarding color and performance are processed into a module.

Central recipe management for cell sorting

CELL-Q’s system and software design simplify the recipe exchange, such as the transfer of quality criteria between systems. This flexibility means that the same quality criteria can be applied across multiple production lines, reducing setup workload for new lines, and enabling true benchmarking of production quality across lines, sites, and equipment.

Easy integration into production lines

CELL-Q combines the functionalities of COL-Q and PRINT-Q in a single system, creating a space-saving and cost-efficient system for sorting cells at the fastest cycle times. CELL-Q is easy to integrate into any sorting unit and can also be integrated bottom-up together with vacuum transport systems

- Contact Grid inspection: Detection of print/pattern defects and monitoring of printing position

- Color sorting: Detection of color and coating defects and cell sorting by color classes

- Detection of other surface and contour defects

- Lowest overkill and underkill rates

- Simple recipe exchange / Recipe Copy-Exact

- Throughputs up to 3800 cells/hr

Download additional information

CELL-Q flyer en

CELL-Q flyer en

CELL-Q flyer en

- Filename

- flyer-cell-q-pro-solar-en.pdf

- Size

- 247 KB

- Format

CELL-Q flyer cn

- Filename

- flyer-cell-q-adv-solar-cn.pdf

- Size

- 474 KB

- Format