Reliable identification of all color and coating defects

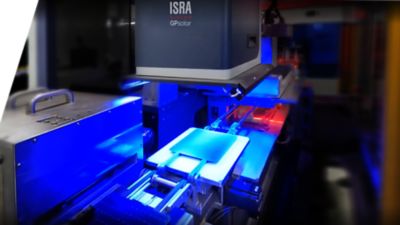

The COL-Q optical inspection system is tailored to the needs of gigawatt-level production facilities and reliably identifies all defects on the cell surface. COL-Q inspects at cycle times <0.7 sec on the fly with uncompromised detection performance.

The distinct MultiView technology precisely detects coating defects such as color deviations, color defects, stains, and local deviations in coating thickness (e.g. caused by pin marks) immediately after coating. A map generated through the assignment of defects to the respective wafer position in the coating process (“Boat View”) then visualizes the spatial distribution of defective or conspicuous cells. This precise detection allows the process parameters to be adjusted quickly in the event of coating defects.

The coated cells are grouped into quality classes based on the coating color, optical coating thickness, homogeneity and detected defects. The system also enables users to automatically remove wafers that do not meet the classification thresholds. As a result, the system both reduces production costs and enables the production of cells with flawless anti-reflection coating.

- Process control of anti reflection coating thickness process by classification of coating-thickness and cell color impression (with HSV and CIELAB color model)

- Quality inspection of single layer, graded layer, and multilayer coatings

- Quality grading of coated wafers based on optical quality of coating color, optical layer thickness, homogeneity, and defects

- Flexible process integration: Inspection possible on the fly or at idle time

- Boat View: Tracking and localization of process deviations

- Multiview technology for best surface defect sensitivity