Security Paper

Deliver flawless security paper that meets your customers’ high standards.

The inspection solutions in our BankSTAR product family give you continuous paper monitoring throughout the entire production process. They inspect the substrate for defects and ensure that all security elements are defect-free. By detecting defects as early as possible within ongoing processes, the systems prevent defective material from further processing, making production more efficient.

Paper Machine Wet Section

BankSTAR PM – WS is ISRA SURFACE VISION’s answer to the particular challenges of optical inspection in the wet section of the paper machine. The system is engineered for operation in the typical rough-and-tough environment of a paper mill, with its usually high levels of humidity and dust. BankSTAR PM – WS is especially designed for the inspection and measurement of all kinds of security threads - including window threads with varying window sizes, flip thread detection and thread elongation assessment -, as well as the detection of dirt, foreign objects and other paper defects that can be optically detected as early as when the pulp is collected by the sieve in the wet section of the paper machine.

Furthermore BankSTAR PM – WS provides precise web and sub-web measurements, thus enabling process parameter optimization with measurement values retrieved from this very early stage of the production process.

Benefits

- Shortest reaction time for operator to fix quality

- Early defect detection

- Documentation of thread and elongation, e.g. for the new Euro

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects like pinholes, inclusions, spots, streaks

- Design/décor defects like missing bits, positioning defects, print defects

- Paper weight 45 - 160 g/m2

- Speed up to 360 m/min

- Width between 400 mm and 1000 mm

- Sheets length up to 1000 mm

Download additional information

asdf

asdf

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

test123

test123

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

Paper Machine Dry End

BankSTAR PM is installed at the dry end of the paper machine and detects the overwhelming majority of critical paper defects before slitting and cutting of the substrate. Inspecting the substrate at this point in the production chain is of paramount importance for production efficiency and quality assurance.

BankSTAR PM’s inspection channel in transmission checks all types of watermarks, e.g., artisanal registered/localized high-resolution watermarks, edge-/cornerstone watermarks, e-types, skew marks and cutting marks, and measures sheet length, width and geometry.

A specific combination of additional inspection channels in reflection enables BankSTAR PM to also detect dirt, inclusions, thin areas and other typical paper defects, as well as ‒ depending on the configuration ‒ low-contrast defects, e.g., wrinkles (double and triple substrate) and streaks, thereby allowing the machine operator to adjust production parameters and eliminate imperfections while they happen. By the same token BankSTAR PM helps the paper mill avoid further processing of defective material.

Benefits

- Easy identification with ink marking unit

- Avoid adding value to defective material

- Exact data on paper geometry

- Precise information on paper quality and capacity of good production

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Paper weight 45 - 160 g/m2

- Speed up to 360 m/min

- Width between 400 mm and 1000 mm

- Sheets length up to 1000 mm

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

Finishing

BankSTAR OV is specifically engineered for the assessment of the integrity and quality of objects and features applied in the converting steps of the security paper production process. The “OV” configuration of BankSTAR performs high-precision inspection tasks in the converting or “OV” line ‒ otherwise known as ”finishing line” or ”application line” ‒, with special focus on the application of holographic objects, iridescent print, primer print and backside foils.

BankSTAR OV is capable of performing extremely complex measurement and inspection tasks, such as checking secure window features with transparent or opaque holograms, where the hole punching, the backside foil and the centered positioning of the hologram feature within the window, as well as its integrity, must be verified.

Benefits

- 100 % inspection of iriodin print

- Recognition of defects during foil application

- Most precise inspection of OVI printing

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

- Substrate defects – pinholes, inclusions, spots, streaks,….

- Design/décor defects – missing bits, positioning defects, print defects,….

- Paper weight 45 - 160 g/m2

- Speed up to 360 m/min

- Width between 400 mm and 1000 mm

- Sheets length up to 1000 mm

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

Cross-Cutter

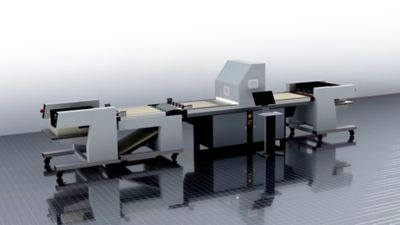

BankSTAR CC is the most versatile and complete of all BankSTAR configurations. Housed in its own vibration-absorbing frame with high-precision rollers in front of the knife at the cross-cutter or sheeter, BankSTAR CC can inspect virtually any feature and detect virtually any defect type in security paper: dirt/spots, thin areas, wrinkles, security threads, holographic features, iridescent printing, etc.

The job of BankSTAR CC is final quality assurance and allocation of sheets to the good, doubtful and bad piles by sending the corresponding output signals to the cross-cutter. Hence, BankSTAR CC enables security paper mills to deliver 100% inspected quality to their customers.

BankSTAR CC has a fail-safe mechanism ensuring that no defective sheets are sent to the bad pile. All sheets are first classified as bad sheets. If a defect is found, this classification is upheld and the sheet is sent to the bad pile. The same happens if there is any technical problem. Only if a sheet is properly processed and no defect is found, that sheet is re-classified as a good sheet and sent to the good pile.

BankSTAR CC interfaces perfectly – both mechanically and logically – with the security paper cross-cutters of all major manufacturers.

Benefits

- Deliver reams with 100 % perfect quality

- No manual hand sorting necessary

- Features

- Typical defects

- Technical data

- High-speed, high-resolution line-scan cameras

- Ultra-bright illumination modules

- Inspection using visible, ultraviolet or infrared light

- Real-time processing

Cutting/slitting defects

- Paper weight 45 - 160 g/m2

- Speed up to 360 m/min

- Width between 400 mm and 1000 mm

- Sheets length up to 1000 mm

Download additional information

Brochure BankSTAR [EN]

- Filename

- brochure-bankstar-security-en.pdf

- Size

- 1 MB

- Format

Brochure BankSTAR gen4 [EN]

- Filename

- brochure-bankstar-gen4-security-en.pdf

- Size

- 403 KB

- Format

Brochure BankSTAR [CN]

- Filename

- brochure-bankstar-security-cn.pdf

- Size

- 2 MB

- Format

생산 분석 - 데이터 기반 생산 효율성

웹 기반 생산 분석 플랫폼을 통해 모든 생산 라인의 시스템 상태를 한눈에 확인하거나 생산 데이터를 세부적으로 분석할 수 있습니다. 품질 관리 시스템을 통해 과거 데이터를 분석하고, 현재 검사 데이터를 실시간으로 모니터링하며, 생산 공정의 향후 추세를 파악할 수 있습니다.

생산 최적화

대시보드를 통해 생산 라인과 제품 데이터를 현장 또는 원격으로 비교하여 최적화를 위한 핵심 인사이트를 얻을 수 있습니다. 이를 통해 가치 사슬 전반에 걸쳐 정보에 입각한 전문적인 의사 결정을 내릴 수 있어 제품 품질과 수익성을 높일 수 있습니다. 최적화 조치의 진행 상황을 지속적으로 추적하고 시각화된 고급 리포트를 통해 이를 제시할 수 있습니다

생산 결함 조기 발견

실시간 상태 정보와 자동 알림을 통해 생산의 모든 단계에서 임계값 위반의 원인을 감지하고 신속하게 파악할 수 있습니다. 그 결과 생산 결함을 신속하게 해결하고 가동 중단 시간을 단축하며 생산 비용을 절감할 수 있습니다.

예측 유지보수

센서와 모니터링 시스템의 실시간 데이터를 분석하여 잠재적인 시스템 장애를 예방할 수 있습니다. 이를 통해 정해진 일정에 따르지 않고 기계의 실제 상태를 기반으로 유지보수를 사전에 계획할 수 있습니다. 이러한 데이터 기반 접근 방식은 다운타임을 줄이고 전반적인 생산성을 높임으로써 비용을 절감할 뿐만 아니라 생산 라인 수명을 연장합니다.

이점

- 시간을 절약하 수 있는 multi-line overview, 모든 품질 관련 정보를 한 번에 볼 수 있는 One view 시스템

- 시스템 상태 데이터 모니터링으로 다운타임 최소화

- 품질 데이터 모니터링으로 품질 문제에 대한 신속한 대응

- 생산 결함의 신속한 제거, 생산 비용 절감

- 유지보수 개선으로 다운타임 감소, 전체 생산성 향상 및 생산 라인 수명 연장

특징

- 생산 데이터 및 공장 상태에 대한 Overview

- 실시간 데이터에서 얻은 Live 로 인사이트 확보

- 웹 기반 솔루션 (클라이언트 소프트웨어 설치 필요 없음)

- 임계값 모니터링 및 경고

- 사업부 중심의 대시보드, 고객별 맞춤 설정 가능

- 관련 타사 데이터 통합 가능 및 고객 시스템으로 데이터 내보내기 가능

맞춤형 서비스 솔루션 및 개별 교육

생산 시스템의 효율적이고 미래 지향적인 운영을 위해 우수한 자격을 갖춘 서비스팀이 모든 문제에 대해 전 세계적으로 고객을 지원합니다. 연중무휴 24시간 신속하고 안정적으로 시스템의 구현, 유지보수 및 서비스는 물론 분석 및 최적화를 제공합니다.

또한 유능한 트레이너를 통해 시스템 운영자, 제품 엔지니어 및 품질 관리자가 진정한 검사 전문가가 될 수 있도록 직원들에게 항상 최신 지식을 제공하는 방법을 알아보시려면 ISRA 아카데미를 방문하세요.