연포장재 인쇄에서의 과제 극복

고품질 패키징은 미적 외관뿐만 아니라 최종 소비자로부터 포장 제품의 품질을 나타내는 지표로 평가받기도 합니다. 따라서 연포장 제조는 복잡한 공정으로 중요한 과제를 안고 있습니다. 가장 일반적인 문제로는 인쇄 품질 결함, 밀봉, 코팅 또는 라미네이션 결함 등이 있습니다.

그 밖에도 폐기물 관리, 고품질 표준을 유지하면서 생산 비용을 절감하는 문제도 있습니다. 이러한 문제를 극복하려면 생산 공정의 모든 단계에서 세심한 주의가 필요합니다.

인쇄부터 마무리 공정까지 정밀한 품질 관리를 통해 최종 제품이 원하는 품질 표준을 충족하도록 해야 합니다. 따라서 자동화된 검사 시스템은 폐기물을 줄이고 비용과 시간을 절약할 수 있는 솔루션입니다.

설정 시간 단축, 완벽한 웹 모니터링, 레지스터에 대한 모든 것

인쇄 프로세스를 설정할 때는 고려해야 할 사항이 많으며 시간도 짧습니다. 이러한 준비 과정에서 낭비를 줄이기 위해 미리 공정을 전체 공정을 최적화할 수 있습니다: 잘못 삽입되거나 결함 있는 인쇄판, 잘못된 텍스트 및 언어 버전은 인쇄를 시작하기 전에 이미 골든 마스터와 고객이 제공한 참조 PDF 파일을 비교하여 식별하고 수정될 수 있습니다.

또한 인쇄 단위는 레지스터에서 설정됩니다. ViewSTAR 웹 시스템의 자동 레지스터 제어가 여기에서 인쇄 단위 설정을 대신할 수 있습니다. 웹 모니터링을 통해 프린터는 선택적으로 개별 인쇄 지점을 고해상도로 확인하거나 개요를 확인할 수 있습니다.

웹 모니터링 시스템 ViewSTAR 는 최상의 해상도와 색상으로 매우 미세한 인쇄 특성과 색상 변화까지 모니터링하며, 추가 인쇄 프로세스에서도 높은 수준의 웹 모니터링을 제공합니다.

인쇄 프로세스 중에 PrintSTAR 검사 시스템의 LiveWebView 기능을 사용하면 작업자가 정밀한 라이브 이미지를 통해 인쇄 프로세스를 더욱 자세히 모니터링할 수 있습니다. 검사된 인쇄 이미지는 별도의 모니터에 표시되며, 사용자는 생산이 진행 중인 동안 현재 이미지를 확대 및 축소하여 특정 영역을 자세히 살펴볼 수 있습니다. 이미지 크기는 반복 길이와 소재 폭에 따라 달라집니다.

이를 통해 인쇄 오류와 롤러의 불필요한 오염을 최소화할 수 있을 뿐만 아니라 준비 과정에서 작업자를 지원할 수 있습니다. LiveWebView가 제공하는 프레스에 대해 끊임 없는 인사이트를 통해 레지스터 동작을 모니터링할 수 있으므로 미세 조정을 위해 인쇄기를 멈추는 데 많은 비용과 시간이 소요되는 프로세스가 사라집니다.

이점

- 제작 준비 프로세스의 높은 수준의 자동화로 재료 비용 및 작업 시간 절감

- LiveWebView를 통해 프레스에 대한 끊임없는 인사이트 제공

- Features

- Typical defects

- Technical data

- 기본 설정의 검사 기능을 확장하는 디지털 지원: PDF 검증용

- 레지스터 제어

- 웹 모니터링

- LiveWebView (실시간 웹 촬영)

- 잘못된 잉크 설정 혹은 플레이트 순서 (잉크 또는 플레이트가 잘못된 인쇄 장치에 있음)

- 잘못된 인쇄판/실린더(잘못된 레이아웃)

- 잘못된 텍스트 또는 언어 버전

- 잘못된 작업 버전

- 인쇄판/실린더 결함

- 검사 폭: 600mm에서 최대 2500mm, 기타 요청 시 가능

자료 다운로드

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Flyer ViewSTAR [EN]

- Filename

- viewstar-flyer-print-en.pdf

- Size

- 796 KB

- Format

Print inspection for flexible packaging [en]

Print inspection for flexible packaging [en]

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

Control the print quality

The ever-increasing demand for brilliant print quality with short throughput times and competitive prices poses challenges for the flexible packaging printing industry. To ensure high image quality, our automatic inspection systems reliably detect recurring or sporadic defects. Sophisticated qualification makes it possible to classify these defects. The classifier distinguishes between serious and negligible defects. Thanks to real-time monitoring and corresponding alarms for serious defects, the operator can intervene in the printing process at any time to eliminate the source of the defect or adjust the process. Stripes, streaks, splashes, missing print images or contamination are quickly detected.

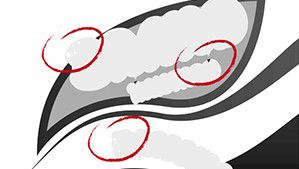

Inspection solutions are also available for toner defects that are difficult to detect, known as hazing (also known as scumming or fogging). Hazing is a slight and even ink transfer in non-image areas caused by a doctor blade, cylinder or ink. On transparent substrates, the defect is invisible to the operator and is only detected in the downstream production process. As a result, the material with the defect must be scrapped and reprinted. Overall, our inspection solutions help to avoid costly misprints and ensure that the end product meets the highest quality standards.

Barcodes and QR codes are now standard on flexible packaging and offer benefits to the consumer or in the sales process. It is crucial that these codes are legible at all times to ensure smooth usage. Unreadable codes are unacceptable and must be avoided. Intelligent inspection systems such as PrintSTAR are able to identify codes with static content and check their legibility. If a code is unreadable, the system triggers an alarm that informs the operator. The operator can then identify and eliminate the causes of illegibility, such as missing print images, ink splashes or other contaminants. This ensures that the codes always work correctly and fulfill their intended functionality.

Benefits

- 100% print inspection in full coverage, anywhere and any time

- Detection of sporadic and/or repeating print defects, which helps your operator to react fast

- More sustainable production processes as waste production can be avoided from the start

- Classification allows for detecting only relevant defects

- Features

- Typical defects

- Technical data

- 헤이징(Hazing) 감지

- 줄무늬(Streak) 감지

- 데이터 마이닝 소프트웨어 EPROMI로 생산 공정을 분석하여 올바른 의사 결정 가능

- 스플래시 및 얼룩

- 누락된 잉크

- 헤이징 (Hazing)

- 레지스터 오류

- 줄무늬 및 드래그

- 먼지

- 검사 폭: 600mm에서 최대 2500mm, 기타 요청 시 가능

자료 다운로드

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

제품의 색상 정확도 향상

정확한 색상은 포장 품질에 있어 가장 중요한 요소 중 하나입니다. 색상의 일관성과 지속적인 색상 측정 및 제어는 매우 중요합니다. 연포장, 퍼스널 케어 제품, 라벨 등 브랜드 제조업체는 완벽한 포장과 균일한 색상이 브랜드 제품의 필수 요소이기 때문에 약간의 색상 오차만 허용하기 어렵습니다.

정확한 색상을 유지하고 색상 값(L*A*B)에 맞게 유지하는 것은 인쇄 공정에서 중요한 작업입니다. PrintSTAR 검사 시스템은 상대 측정값을 통해 이를 추적할 수 있는 ColorWatch 기능을 제공합니다.

추가 하드웨어 없이 RGB 라인 스캔 카메라를 사용하여 기준 이미지와의 색상 편차를 감지할 수 있습니다. DeltaE 값이 측정되고 지속적으로 표시되며, 원하는 모든 위치를 측정할 수 있을 뿐만 아니라 단색 또는 하프톤도 측정할 수 있습니다.

이 기능을 향상시킨 ColorSTAR의 절대 색상 측정 기능은 상대 색상 값(L*a*b*)을 지속적으로 측정하고 모니터링할 수 있도록 해줍니다.

이점

- 투명 호일을 포함한 모든 물질에 적합

- 제한 없는 측정 위치

- 색상 관리를 위한 고유한 컨셉: 언제 어디서나 반복할 때마다 필요한 만큼 많은 영역 측정 가능

- 폐기물 및 Cut-out 샘플 감소

- 실시간 측정으로 최상의 피드백을 제공하여 준비 시간을 단축하고 비용을 절감

- Features

- Typical defects

- 상대적 색상 측정을 위한 ColorWatch

- 색상 정확도 극대화를 위한 ColorSTAR 인라인 색상 측정

- 색상 측정 표준에 따른 분광광도계

- 추가 트랙 장비 없이 신축성이 있는 얇은 소재 포함 모든 종류의 소재에 대한 측정 위치를 지속적으로 자동 추적 가능

- 전체 라인 폭에 걸친 동시 색상 편차 측정

- 도트 게인(dot gain) 및 밀도에 대한 리포트 및 모니터링 제공

- 색상 편차

자료 다운로드

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Flyer ColorSTAR [EN]

- Filename

- MVS-PR-FL-ColorSTAR-EN-062024.pdf

- Size

- 760 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

레지스터에서 콜드씰(Cold-seal) 유지

콜드실 패키징은 빠른 유통과 용도 및 패키징 사양에 맞는 접착제로 높은 공정 속도와 다양한 접착 강도를 보장하는 등 포장업체에 많은 이점을 제공합니다. 그러나 밀봉 누락이나 접착제 오염과 같은 밀봉 결함은 이러한 장점을 빠르게 파괴할 수 있습니다. 인라인 검사 시스템을 사용하면 이러한 결함을 최대한 빨리 감지하고 제거할 수 있습니다. 콜드실 패키징에서 중요한 또다른 포인트는 앞면과 뒷면의 레지스터 정확도입니다. 여기에는 특별한 ISRA 기술이 사용됩니다:

PrintSTAR 시스템은 중첩된 이미지로 기판의 앞면과 뒷면을 동시에 검사합니다. 뒷면의 실링 레이어가 앞면의 인쇄 이미지와 정확히 일치하지 않으면 알람 신호가 작업자에게 즉시 울립니다.

이 획기적인 검사의 또 다른 장점은 공정 속도를 늦추는 레지스터 마크를 제거할 수 있어 필요한 필름 폭을 줄이고 재료 비용을 절감할 수 있다는 것입니다.

이점

- 폐기물 감소

- 레지스터 마크 불필요

- Features

- Typical defects

- 앞뒤 연속 레지스트레이션

- 오염

- 실런트 누락

- 청크(Chunks)

- 전면 및 후면 레지스트레이션 결함

자료 다운로드

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

완벽한 품질의 바니쉬 보호 및 후처리 바니쉬

바니쉬는 인쇄 공정에서 고급 마감, 특수 효과 또는 보호 기능을 제공합니다. 간단 엠보싱, 광택 또는 소프트 터치 효과 또는 은색 및 금색 안료가 포함된 특수 인쇄는 인쇄된 제품의 고유한 품질과 가치를 보장하기 위해 100% 완벽해야 합니다. 그 외에도 이 시스템은 특별한 경우에 필요한 오버프린트 바니쉬도 검사할 수 있습니다.

ISRA VISION은 100% 인라인 검사를 통해 웹의 앞면과 뒷면 모두에서 바니쉬 결함을 종합적이고 안정적으로 검사할 수 있습니다. 이 시스템은 고속 고해상도 라인 스캔 카메라와 최고 수준 밝기의 특수 LED 조명을 갖춘 이미지 캡처 장치를 영구 설치하여 사용합니다.

이점

- 광범위한 코팅 및 라미네이션 기술에서 결함 감지

- 레지스터 정확도 확인

- 지속적이고 완벽한 공정 제어

- Features

- Typical defects

- Technical data

- MultiView

- 스크래치

- 스플래시(Splashes)

- 스머지(Smudges)

- 불균일한 코팅

- Inspection width: from 600 mm up to 2500 mm; others on request

Download additional information

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

Ensure flawless coatings & lamination

During the lamination process, films can exhibit various types of defects, including wrinkles, inclusions, bubbles and foreign bodies. Detecting such defects, some of which are very small, with the naked eye is often difficult. In addition, manual inspection is subjective and depends heavily on the experience and expertise of the inspector, which can lead to inconsistencies in defect detection.

Another critical challenge is that films are often produced at high speed, which requires fast and accurate inspection. It is therefore advisable to play it safe!

Leave the quality control to our automatic inspection systems. They offer the fastest image capture rate in the industry and reliably detect all typical defects that can occur during the lamination process.

Our seamless inline print inspection system inspects webs simultaneously from above and below. As a result, the system detects defects on the front and back simultaneously and is suitable for a wide range of coating and lamination techniques. Finally, our system guarantees continuous and seamless process control that comprehensively covers the print image, lamination and coating.

Benefits

- Detection of all typical lamination defects

- Continuous and seamless process control

- Features

- Typical defects

- Technical data

- Inspection of coatings and laminations

- Permanently installed image acquisition units

- Fast, high-resolution line scan cameras

- Ultra-bright LED lighting

- Folds

- Inclusions

- Bubbles

- Contamination

- Delamination

- Missing coating

- Inspection width: from 600 mm up to 2500 mm

Download additional information

Flyer PrintSTAR EVO [EN]

- Filename

- MVS-PR-FL-PrintSTAR-EVO-EN-062024.pdf

- Size

- 910 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

Guaranteed converting and slitting quality

When it comes to further processing at the end of the production chain, with process steps such as winding or slitting, outstanding quality is crucial. Precise adjustment of the slitter width, optimum roll density and tension are essential to avoid problems. This becomes particularly challenging when both unprinted and printed films are processed on the same machine.

Our inspection systems are designed to inspect both unprinted and printed substrates in a single system. Equipped with functions such as the RewindManager, which enables the automated removal of waste.

By linking to a synchronized database, the user can select which defects should be rectified to maximize the value of a production roll. In addition, we also monitor the final steps of the production process.

The PrintTrack function monitors the web for stretch and alerts the operator if a threshold value is exceeded. This is conveniently displayed in a trend graph. We also monitor the web position so that the knife positions can be adjusted for the cutting process. This results in less waste and higher quality end products.

Benefits

- Elimination of faults in every roll

- Longer machine running times

- Highest quality for all converting processes

- Maximum production efficiency and quality

- Reduction of rejects

- Features

- Automatic removal of waste in the finishing department

- Inspection of a printed and unprinted film with one single system

- ReWind Manager

- Monitoring of web stretching

Download additional information

Flyer DualSTAR [EN]

- Filename

- MVS-PR-FL-DualSTAR-EN-062024.pdf

- Size

- 470 KB

- Format

Brochure Flexible Packaging [EN]

- Filename

- MVS_PR_BR_FlexiblePackaging_EN_2024_08_low.pdf

- Size

- 5 MB

- Format

생산 분석 - 데이터 기반 생산 효율성

웹 기반 생산 분석 플랫폼을 통해 모든 생산 라인의 시스템 상태를 한눈에 확인하거나 생산 데이터를 세부적으로 분석할 수 있습니다. 품질 관리 시스템을 통해 과거 데이터를 분석하고, 현재 검사 데이터를 실시간으로 모니터링하며, 생산 공정의 향후 추세를 파악할 수 있습니다.

생산 최적화

대시보드를 통해 생산 라인과 제품 데이터를 현장 또는 원격으로 비교하여 최적화를 위한 핵심 인사이트를 얻을 수 있습니다. 이를 통해 가치 사슬 전반에 걸쳐 정보에 입각한 전문적인 의사 결정을 내릴 수 있어 제품 품질과 수익성을 높일 수 있습니다. 최적화 조치의 진행 상황을 지속적으로 추적하고 시각화된 고급 리포트를 통해 이를 제시할 수 있습니다

생산 결함 조기 발견

실시간 상태 정보와 자동 알림을 통해 생산의 모든 단계에서 임계값 위반의 원인을 감지하고 신속하게 파악할 수 있습니다. 그 결과 생산 결함을 신속하게 해결하고 가동 중단 시간을 단축하며 생산 비용을 절감할 수 있습니다.

예측 유지보수

센서와 모니터링 시스템의 실시간 데이터를 분석하여 잠재적인 시스템 장애를 예방할 수 있습니다. 이를 통해 정해진 일정에 따르지 않고 기계의 실제 상태를 기반으로 유지보수를 사전에 계획할 수 있습니다. 이러한 데이터 기반 접근 방식은 다운타임을 줄이고 전반적인 생산성을 높임으로써 비용을 절감할 뿐만 아니라 생산 라인 수명을 연장합니다.

이점

- 시간을 절약하 수 있는 multi-line overview, 모든 품질 관련 정보를 한 번에 볼 수 있는 One view 시스템

- 시스템 상태 데이터 모니터링으로 다운타임 최소화

- 품질 데이터 모니터링으로 품질 문제에 대한 신속한 대응

- 생산 결함의 신속한 제거, 생산 비용 절감

- 유지보수 개선으로 다운타임 감소, 전체 생산성 향상 및 생산 라인 수명 연장

특징

- 생산 데이터 및 공장 상태에 대한 Overview

- 실시간 데이터에서 얻은 Live 로 인사이트 확보

- 웹 기반 솔루션 (클라이언트 소프트웨어 설치 필요 없음)

- 임계값 모니터링 및 경고

- 사업부 중심의 대시보드, 고객별 맞춤 설정 가능

- 관련 타사 데이터 통합 가능 및 고객 시스템으로 데이터 내보내기 가능

맞춤형 서비스 솔루션 및 개별 교육

생산 시스템의 효율적이고 미래 지향적인 운영을 위해 우수한 자격을 갖춘 서비스팀이 모든 문제에 대해 전 세계적으로 고객을 지원합니다. 연중무휴 24시간 신속하고 안정적으로 시스템의 구현, 유지보수 및 서비스는 물론 분석 및 최적화를 제공합니다.

또한 유능한 트레이너를 통해 시스템 운영자, 제품 엔지니어 및 품질 관리자가 진정한 검사 전문가가 될 수 있도록 직원들에게 항상 최신 지식을 제공하는 방법을 알아보시려면 ISRA 아카데미를 방문하세요.