Vision solutions for EV battery production

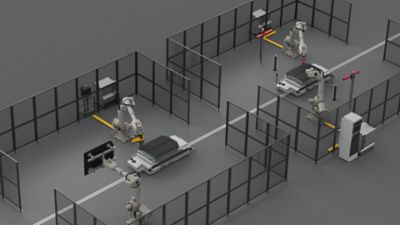

Intelligent vision systems provide the key to higher productivity, greater efficiency and total quality assurance and help manufacturers achieve highest product quality, consistency in the production and minimizing waste.

Machine vision solutions can be used in several steps of the lithium battery production such as battery module assembly, Cell stack assembly; gap filler applications, tightening of modules, cover sealing and cover to tray assembly.

Pick & Place

The final step of battery assembly is the mounting of the cover onto the battery tray. When joining a battery cover to its tray, more than 100 fasteners can be needed. This requires a fast application to achieve a short cycle time.

Precise positioning of the joining tool is crucial for the assembly process step to deliver the highest quality standards. MONO 3D performs pick-and-place of battery covers precisely and enables fast and reliable robot guidance which is the key driver for high-volume production. Fast image processing algorithms during computing increase the speed and accuracy of the tightening process. The MONOxD Software calculates the 3D coordinate transformation and sends the offset to the robot controller to optimize the tool path.

Benefits

- Excellent process reliability, efficiency, and quality

- Reliable production processes

- Ready to use in hours with any robot

- Full flexibility for handling different kind of parts

- Easy-to-use software with graphical user interface

- Online-Teaching for a quick and easy handling of system during operation without loss of production time

- Features

- Technical data

- Intuitive user interface and can be used without any expert knowledge

- New component shapes can be configured in just a few hours

- Compatible with all common robot types

- Suitable for stationary and robot mounting

- Cycle time below 500ms

- Efficient object position determination in 4 degrees = x, y, z and Rz

- Low space requirements and ease of integration in confined spaces

Bead Inspection

To meet the high safety and performance requirements of battery manufacturing, the thermal compound material must be applied continuously, in the right position, width, and height. Only balanced and sufficient material distribution for optimal conductivity and heat dissipation avoids battery defects. RTVision.3d is the ideal solution for inspecting bead quality as it can measure not only the width, position, and continuity of the bead application, but also its height.

Benefits

- Ensure an optimal conductivity and heat dissipation

- Avoid manual rework or even scrap of the part

- Get immediate feedback, if an error has been detected

- Features

- Typical defects

- Technical data

- 100% 3D inline solution for adhesive application in battery manufacturing

- Covering all bead geometries

- Automatic bead repair function

- Widt deviations

- Position deviations

- Height deviations

- Gaps

- ± 0.1mm accuracy in width

- ± 0.1mm accuracy in position

- ± 0.1mm accuracy in height

- ± 0.1mm accuracy in adhesive gaps

Download additional information

- English

- German

- Chinese

QUISS RTVision brochure en

- Filename

- brochure-quiss-rtvision-automotive-en.pdf

- Size

- 495 KB

- Format

RTVision.3d [EN]

- Filename

- mvs-sfa-fl-rtvision-3d-en-2025-01.pdf

- Size

- 764 KB

- Format

QUISS RTVision.t brochure en

QUISS RTVision.t brochure en

RTVision.t [EN]

- Filename

- mvs-sfa-fl-rtvision-t-en-2024-12_web.pdf

- Size

- 737 KB

- Format

asdf

asdf

QUISS RTVision brochure de

- Filename

- brochure-quiss-rtvision-automotive-de.pdf

- Size

- 497 KB

- Format

asdf

QUISS RTVision brochure cn

- Filename

- brochure-quiss-rtvision-automotive-cn.pdf

- Size

- 623 KB

- Format

QUISS RTVision.3d brochure cn

- Filename

- brochure-quiss-rtvision3d-automotive-cn.pdf

- Size

- 811 KB

- Format

QUISS RTVision.t brochure cn

- Filename

- brochure-quiss-rtvisiont-automotive-cn.pdf

- Size

- 611 KB

- Format

Tightening

Following the quality inspection, a multispindle with MONO3D robot guidance allows a perfect tightening process. Fast image processing algorithms during computing increase the speed and accuracy of the tightening process. The MONOxD Software calculates the 3D coordinate transformation and sends the offset to the robot controller to optimize the tool path.

Benefits

- Maximum process accuracy

- Increased process efficiency and quality

- Features

- Technical data

- Precise and efficient object position determination in 4 degrees: x, y, z and Rz

- Fast image processing and offset provision

- Large field of view depending on working distance

- Low space requirements and ease of integration

- Cycle time below 500 ms

Fire Protection

In the event of a battery cell fire, it is essential that passengers have sufficient time to exit the vehicle safely. A 2-component fire protection material can be applied to delay the spread of flames. However, the effective application of this material requires a seamless and highly accurate flat stream application.

Quiss bead inspection solutions control the precise material application to ensure it is correct.

Benefits

- Easy to retrofit in existing systems

- Improved quality: Direct feedback on the volume applied to catch quality issues immediately

- Inline-inspection – no additional cycle time

- Automated bead repair function available

- Features

- Typical defects

- Monitoring of adhesive application in battery manufacturing

- Inspection of all conventional adhesive and sealant application types and colors

- Checks the adhesive or sealant bead’s position, width, and continuity

- Gaps

- Width deviations

- Position deviations

Download additional information

Brochure QUISS RTVision [EN]

- Filename

- brochure-quiss-rtvision-automotive-en.pdf

- Size

- 495 KB

- Format

RTVision.3d [EN]

- Filename

- mvs-sfa-fl-rtvision-3d-en-2025-01.pdf

- Size

- 764 KB

- Format

RTVision.t [EN]

- Filename

- mvs-sfa-fl-rtvision-t-en-2024-12_web.pdf

- Size

- 737 KB

- Format

Foreign Part Detection

After dispensing the compound thermal material, the module needs to be mounted and tightened to the battery tray.

To avoid serious production quality issues and achieve short cycle times, the PowerPICK3D sensor ensures foreign part free assembly situation with its ultra-fast quality inspection and result provision. After acquiring the point cloud, the embedded processing unit compares the point cloud generated in production environment and calculates deviations from the CAD-file based on tolerances defined.

Benefits

- Foreign object and contamination detection ensures a collision-free assembly process

- Consistently high and reliable level of inspection quality based on 3D images

- Overall process quality depends on accuracy and reliability of vision technology

- Reliable solution: High precision and maximum robustness

- Features

- Typical defects

- Recognition of very small foreign objects, irrespective of their geometry or material, e.g. bolts, nuts, screws, nuts

- Robust against shiny surfaces (blue LED projection)

- High accuracy

- Detection of foreign parts > 5mm

- Ultra-fast measurement time < 500ms (embedded processing unit)

- Point cloud acquisition with embedded processing unit

Presence / Absence

Presence or absence detection is a crucial process step in the battery assembly process since it ensures the quality and completeness of the finished product.

Automated visual inspection systems ensure that a specific feature or component is present in the product being made and that no defective or incorrect components arrive at the next manufacturing stage or the end customer.

Stationary or mobile cameras inspect assemblies and components for specified properties, including completeness, presence, and correct position. Defective components can be removed or reworked immediately. This ensures that production meets the quality requirements of the downstream processes to 100%.

Benefits

- Unlimited flexibility and ease of use

- Combination of all modules possible

- Features

- Configurable applications

- Integrated sequence control

- Suitable for any 2D application

- Standardized user interface

- Multiple image processing tools integrated

- Open interfaces

Inline Gauging

When it comes to battery production, customer safety is the top priority. Perceptron's accurate, 100% inline measurement solution measures every battery tray and cover before they are attached to ensure all holes, studs, and mating surfaces meet design specifications.

Missing or out-of-tolerance attachment features between the tray and cover could cause production problems and even severe injuries if the alignment is incorrect.

Benefits

- Find and fix problems at their source

- Reduce process variation

- Improve quality

- 100% quality traceability

- Features

- Technical data

- 100% automated, non-contact measurement

- Robotic or structure mounted configurations

- SPC and GD&T reporting options

- Export and import data upstream or downstream to optimize your build process

- Measurements in less than <2.5 secs.

- System accuracy of 150 microns

Production analytics - Data-driven efficiency

The web-based production analytics platform allows you to check the system status of all production lines at a glance or analyze production data in detail. With the quality management system, you analyze historical data, monitor current inspection data in real-time, and identify future trends in your production process.

Early detection of production defects

Detect and quickly identify the cause of threshold value violations at every stage of production with live status information and automatic alerts. As a result you can quickly resolve production defects, shorten downtime, and reduce production costs.

Predictive maintenance

You can prevent potential system failures by analyzing real-time data from the sensors and monitoring systems. This allows proactive planning of maintenance, based on the actual condition of the machines, instead of following a fixed schedule. This data-driven approach saves costs through reduced downtime and increased overall productivity, as well as longer production line life.

Optimization of production

Dashboards allow you to compare production line and product data onsite or remotely, providing key insights for optimization. This enables you to make informed professional decisions along your value chain to increase the product quality as well as profitability. You can continuously track the progress of optimization measures and present them with visualized advanced reports.

Your benefits

- Time-saving multi-line overviews, one view for all quality-related information

- Minimize downtime by monitoring system health data

- Faster reaction to quality issues with quality data monitoring

- Fast elimination of production defects, reduction of production costs

- Improved maintenance for reduced downtime, higher overall productivity and longer production line life

Key Features

- Overview on production data and plant status

- Live insights from real time data

- Department oriented dashboards, customer specific adaptations are possible

- Web-based solution, no client software installation required

- Threshold monitoring and alerting

- Open to integrate relevant third-party data and export data to the customer's systems

Service solutions and individual trainings

For the efficient and future-proof operation of your production systems our highly qualified service teams support you globally in all matters. We provide the implementation, maintenance and servicing as well as the analysis and optimization of your systems.

Learn in the ISRA VISION Academy how our competent trainers always keep your employees up to date with the latest knowledge so that system operators, product engineers and quality managers become real inspection experts.