Paper, pulp, board and tissue inspection

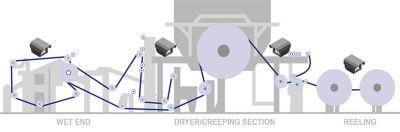

Paper Machine

Paper Machine

In today´s paper, pulp, board, and tissue production, web breaks and a range of other substrate defects present a significant issue in all types of paper machines, coaters, and converting operations. Reducing breaks and paper defects is an important objective given the increasing speed and operating complexities of the present production environment.

ISRA VISION´s complete set of camera-based web monitoring and inspection systems covers the entire process chain from pulp to reel. In addition, our systems and software solutions help to optimize the entire production chain – from headbox to the ultimate delivery of the manufactured product to the customers.

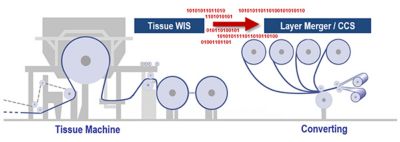

Tissue Machine

Tissue Machine

This complete inspection setup enables manufacturers to significantly reduce costs caused by avoidable web breaks in the slitting and winding process, while accurate defect reports for each cut roll offer 100% production documentation.

Typically, savings of 500.000 €/annum can be realized by implementing the complete inspection suite.

Webbreak Monitoring

All installed components in a paper machine are exposed to harsh environments with dirt, moisture, and high temperatures in which optical-electronic devices operate very delicately. On top of that, a reduction in maintenance costs is always a welcome addition.

To withstand these environmental conditions and minimize exposure, ISRA WBM System utilizes a special housing for the high-performance camera for web break analysis that always guarantees perfect image quality. Even the smallest details become visible with the camera so that faults can be automatically detected early in the development process and stopped in time before costly events occur.

Benefits

- Reduce web breaks by at least 50% with the best performing unified system (WIS / WBM / UCS).

- Detect even the tiniest defects in the µm range at web speeds of up to 2,000 meters per minute.

- Sustainable process stabilization to reduce your carbon footprint

- Process efficiency and product optimization by production analytics

- Integrated inspection solution from wet to door

- Features

- Typical defects

- Technical data

- Crystal clear images

- Excellent video root cause analysis for fast corrective action

- All-in-one: Compact, ruggedized stainless steel housing including camera, processing, illumination and cleaning

- Easy to install even in challenging environments with limited spaces, dirt, water and heat

- Automated razorblade or brush cleaning

- Real-time information to reduce web breaks typically by 50 %

Dirt

Holes

Wrinkles

Bitumen

Edge cracks

Formation defects

Designed for the following web speeds:

- Paper machines up to 2.000 m/min

- Tissue machines up to 2.300 m/min

Web Inspection

The Web Inspection System (WIS) captures high-resolution defect images over the full web width even at the highest web speeds with high-speed line cameras - or area cameras - and innovative lighting technology. For such a WIS systems, even though paper is mostly monochrome, the use of color cameras in the paper machine provides advantages. The classification gets a significant boost as low contrast defects cannot be detected by black-and-white cameras and could be missed. Plus, it´s now possible to distinguish between an oil and a water drop - a certainly important feature for error source analysis.

Benefits

- Easy configuration and integration

- Guarantee highest quality standards and customer satisfaction

- Perfect defect image quality at highest speeds

- Increase production efficiency and maximize throughput

- Reduce machine degeneration and maintenance, increase machine uptime

- Monitor yield at all production stages and reduce manufacturing costs

- Features

- Typical defects

- Technical data

- Latest, fastest high-resolution camera and integrated optical technology

- Highest detection performance down to microns

- Best single- and multilayer detection results

- Ensuring 100 % defect detection at highest production speeds

- Outstanding defect classification within shortest time

- Dirt

- Wrinkles

- Bitumen

- Edge cracks

- Formation defects

Designed for the following web speeds:

- Paper machines up to 2.000 m/min

- Tissue machines up to 2.300 m/min

Unwind / Converting Control System

Converting Control System

To reduce web breaks and costs in the further processing of tissue products, the Converting Control System (CCS) detects surface defects logged by the inspection system on the Tissue machine. At double-width tissue machines, an additional middle-cut detection, inspecting the quality of the edges along the cut is done, and the production data is stored for later processing and retrieval. The CCS enables synchronization of the defect positions on the different layers. The layer-independent defect position to control the speed of the converting line is then transmitted by the CCS. Thus, web breaks will be drastically reduced in tissue converting lines.

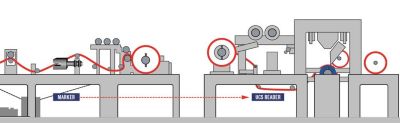

Unwind Control System - Laser Marker

The flexible Unwind Control System accurately assigns defects and precisely synchronizes the defect database for each roll using a code marking applied to the web edge. This ensures that defects can be clearly assigned by location on the sheet in the next production stage, regardless of paper losses incurred in the process.

The UCS can be integrated at various points in the process, such as the reeler, the offline coating, calenders, or winder.

To achieve an exact position synchronization between the defect database of the jumbo-reel, the application of a length code along the edge of the paper web is used. To date, length codes have been applied with conventional inkjet marking systems that cause costs due to regular cleaning, and high consumption of ink.

In addition, possible ink contamination of the substrate can occur, leading to customer complaints. ISRA´s UCS Laser Marker overcomes these limitations by using an absolutely safe and reliable laser-based length code marking system with maintenance and consumables costs that are almost zero. In addition, distances between the individual length marks can be drastically reduced, and laser-based marking systems are suitable for nearly all paper grades.

Benefits

- Unwind Control System: Accurate defect assignment: Precisely synchronizes the defect database for each roll - for a clear fault assignment and maximum availability of the winder.

- Features

- Technical data

Unwind Control System:

- Cutting-edge code marking tec

- LaserMarker: virtually maintenance free, no consumables

- InkMarker for Tissue & Light Weight Papers

- Exact sychronisation

- Comparision of position with defect database technology

Designed for web speeds up to 3.000 m/min

Paper Quality Management System

A WBM or WIS cannot achieve the level of optimization without the software that connects all the bits and pieces of information gathered from sensors and cameras. PAPER MASTER 4.0 is the first browser-based platform for surface analysis to access the data of the ISRA system from anywhere, whether it be directly at the production line, in a meeting room, or on the road, by simply using mobile devices such as a tablet or a smartphone.

PAPER MASTER 4.0 combines all data from the ISRA inspection and web break monitoring systems, the slitter and winder control, with all the software modules, in our paper quality management system on one browser-based platform. A new, modern, and intuitive user interface makes data access even easier.

Benefits

- Paper quality management (Yield management, Production analytics, Product data optimization)

- Features

Roll Release, Repair & Reassignment (Grading)

Monitoring & Alarming

Production Analytics

Die webbasierte Production Analytics Plattform ermöglicht es Ihnen, den Systemstatus aller Produktionslinien auf einen Blick zu überprüfen oder Produktionsdaten im Detail zu analysieren.

Mit dem Qualitätsmanagementsystem analysieren Sie historische Daten, überwachen aktuelle Prüfdaten in Echtzeit und ermitteln zukünftige Trends in Ihrem Produktionsprozess.

Optimierung der Produktion

Über Dashboards können Sie die Daten der Produktionslinie und des Produkts vor Ort oder von unterwegs aus vergleichen und erhalten so wichtige Erkenntnisse für die Optimierung. So treffen Sie fundierte Entscheidungen entlang Ihrer Wertschöpfungskette, um die Produktqualität und die Rentabilität zu steigern. Die Fortschritte der Optimierungsmaßnahmen können Sie kontinuierlich verfolgen und mit visualisierten, erweiterten Berichten darstellen.

Frühzeitiges Erkennen von Produktionsfehlern

Grenzwertüberschreitungen können Sie in jedem Produktionsschritt, mithilfe von Live-Statusinformationen und automatischen Warnmeldungen schnell erkennen und deren Ursache finden. Damit lösen Sie Produktionsfehler schnell, verkürzen Ausfallzeiten und senken die Produktionskosten.

Vorausschauende Wartung

Potenzielle Anlagenausfälle können Sie durch die Analyse von Echtzeitdaten aus den Sensoren und Überwachungssystemen verhindern. Dies ermöglicht eine proaktive Planung der Wartung, die auf dem tatsächlichen Zustand der Maschinen basiert, anstatt einem festen Zeitplan zu folgen. Dieser datengestützte Ansatz spart Kosten durch geringere Ausfallzeiten und erhöht die Gesamtproduktivität sowie die Lebensdauer der Produktionslinie.

Ihre Vorteile

- Zeitsparende mehrzeilige Übersichten, eine Ansicht für alle qualitätsbezogenen Informationen

- Minimierung von Ausfallzeiten durch Überwachung der Systemzustandsdaten

- Schnellere Reaktion auf Qualitätsprobleme durch Überwachung der Qualitätsdaten

- Schnelle Beseitigung von Produktionsfehlern, Reduzierung der Produktionskosten

- Verbesserte Wartung für geringere Ausfallzeiten, höhere Gesamtproduktivität und längere Lebensdauer der Produktionslinie

Funktionen

- Überblick über Produktionsdaten und Anlagenstatus

- Webbasierte Lösung, keine Installation von Client-Software erforderlich

- Abteilungsbezogene Dashboards, kundenspezifische Anpassungen sind möglich

- Live-Einblicke aus Echtzeitdaten

- Offen für die Integration relevanter Drittdaten und den Export von Daten in die Systeme des Kunden

- Schwellenwertüberwachung und Alarmierung

Servicelösungen und Schulungen

Für den effizienten und zukunftssicheren Betrieb Ihrer Produktionsanlagen unterstützen Sie unsere hochqualifizierten Serviceteams weltweit in allen Belangen. Wir übernehmen die Implementierung, Wartung und Instandhaltung sowie die Analyse und Optimierung Ihrer Anlagen.

Lernen Sie in der ISRA VISION Academy, wie unsere kompetenten Trainer Ihre Mitarbeiter immer auf dem neuesten Stand des Wissens halten, damit Anlagenbediener, Produktingenieure und Qualitätsmanager zu echten Inspektions-Experten werden.